700 Horsepower

Every hot-rodder knows that it is never long before you want more power, and this 700 horsepower, pump gas 403ci LS engine is another example of horsepower escalation. Initially, Steven Balusik just wanted the additional torque of the long-arm crankshaft to help move his 3,700 pound street car. That was easy enough; toss a stroker kit in his current 6.0-liter LS engine, right? And so the descent down the slippery slope of engine building began. Fast Forward Race Engines in New Port Richey, Florida, was tapped to provide machine work and assembly for the bullet.

Practicality took center stage when block selection was considered — since Balusik didn't want to have the car down-and-out while the short-block was built, he took the route of simplicity and chose to anchor the build with a brand-new LS2 aluminum block from Chevrolet Performance Parts. In addition to starting an engine build with a brand-new block, a weight savings of 100 pounds was realized with this choice.

The engine is destined for the owner's 1965 Buick Skylark. The car tips the scales at 3,700 pounds; the engine will be backed by one of Circle D's 245 mm billet nitrous converters mated to a 200-4R transmission. 3.73:1 gears provide the necessary motivation as the car puts the power down on a 275-wide drag radial tire.

Increasing the stroke means that more camshaft can be added to the combination to take advantage of the added displacement. It would be a waste not to do so, right? While discussing the specs for the new solid roller camshaft, Cam Motion's Kip Fabre felt strongly that this engine needed a better cylinder head to achieve its potential. Respecting Fabre's tremendous experience, it seemed foolish not to take his advice. Again, just being practical with the goals for the project.

Enter the new Dart Pro 1 LS3 cylinder heads into the equation, previously covered extensively in this article. Since the existing LS2 cylinder heads had the LS's cathedral port configuration, and the new Dart heads use the LS3's square port design and wider valve spacing, the existing rocker arms and intake manifold would also need to be replaced — and those were the last of the old engine parts that could be re-used. Somehow, what started as a simple stroker kit installation has turned into a complete engine build. Around here, it's called 'mission creep,' and it often results in large horsepower gains and smiling faces at the end of a project.

Game on.

The Build

Once the Callies 4.000-inch stroke crankshaft, Compstar connecting rods and 11.5:1-compression CP pistons arrived, it was time to tear into the engine.

To begin the build, the new LS2 block was checked out, honed, deburred, machined for the additional stroke, then assembled by Joe Irwin and the gang at Fast Forward Racing Engines. Irwin says that the block's machine work was very good as delivered from CPP; clearancing it for the 4.000-inch crankshaft stroke required little tweaking to achieve his desired tolerances.

Seen here are the crowns and underside of the CP pistons along with the rings, chromoly wrist pins and round wire pin locks. The pistons are designed using Finite Element Analysis, manufactured in the USA from 2618 alloy for strength and durability, and feature dual forced pin oiling. The rotating assembly is balanced to +/- 1 gram.

Setting up the engine's desired tolerances yielded main bearing oil clearance ranging from .0021-inch to .0023-inch. Irwin then set the connecting rod bearing oil clearance to .0026-inch to help the engine achieve his desired oil pressure. With a compression height of 1.110-inch, the pistons are .005-inch below the deck when assembled. Fel-Pro head gaskets measuring .041-inch thick achieved .046-inch quench.

Once cleaned and in the engine assembly room, the rotating assembly was carefully mocked up in the block to ensure proper fitment, then the rings were file-fit to match each cylinder before assembly. 'We mock up all new engine builds to ensure everything goes together smoothly, so there are no surprises for final assembly,' says Irwin.

A Callies one piece billet 24x reluctor wheel was welded to the crankshaft to assure it would not move during operation. Once assembled, the reluctor wheel was checked for runout to assure a good signal to the ignition.

Once the short-block was assembled, it was time to turn attention to the cylinder heads. They were delivered as-cast with some hand blending under the seats. The heads feature 2.165-inch diameter intake valves and 1.600-inch diameter exhaust valves for this application. This new cylinder head design's 370 cfm intake port and 250 cfm exhaust port guaranteed that this engine would have all of the flow it needed to realize its full potential. For this build the owner chose hollow stem LS3 intake valves to save weight and help with valvetrain stability.

The completed short-block awaiting the next steps of the assembly process.

The factory 2.165-inch LS3 intake valves feature hollow stem construction, which keeps the weight per valve down to an extraordinarily-light 89 grams each.

The heads were milled from Dart's 68 cc chamber volume to 65 cc; when paired with the .041-inch-thick head gaskets, the 403 cubic inch LS checks in with an 11.51:1 compression ratio.

The Pro 1 cylinder heads feature a six-bolt design to take advantage of the extra clamping force available when used with the Dart LS Next and GMPP LSX blocks, although that feature is not used in this particular build.

The camshaft chosen for the build is a Cam Motion LLR solid roller design with 247 degrees of intake duration and 259 degrees of exhaust duration at .050-inch lift. Net lift comes in at .661-inch on the intake side and .650-inch on the exhaust side. The lobe separation angle is 110.5 degrees, and the camshaft is installed on a 107-degree intake centerline.

Irwin says the Dart Pro1 LS3 cylinder head casting quality and consistency was excellent. Here you can see the high-quality as-cast port shape surface.

The lifters are Cam Motion tie-bar style solid roller tappets that feature a .750-inch wheel diameter and pressure axle oiling. A PAC 1208X spring kit with titanium retainers was used to control the valve train.

During the mock up process, Balusik discovered that the cylinder heads needed to be slightly modified to clear the T&D shaft-mounted rocker arm mounting stands. In addition, the larger diameter 3/8-inch pushrods required some extra clearance be ground into that area to ensure no unwanted contact takes place. The accompanying photos illustrate the machining that was necessary to achieve the requisite clearance. Once the rocker arms and pushrods were fitted, the rocker arm's contact pattern was checked on the valve tips to assure proper alignment.

The 8620 Carburized Nickel-Chromium-Molybdenum steel alloy camshafts are Cam Motion's best units. The hardening process the camshaft undergoes during manufacturing creates a durable wear surface while maintaining excellent ductility. The lobes on this low-lash solid roller camshaft are designed to be easy on valvetrain components. Once in the block, the camshaft's intake centerline location was checked using a degree wheel to ensure proper installation and cam timing events.

Topping off this combination is a port matched and plenum blended Edelbrock Victor Jr. intake manifold, which has also been machined to accept a 4500-series carburetor should the need for extra fueling arise.

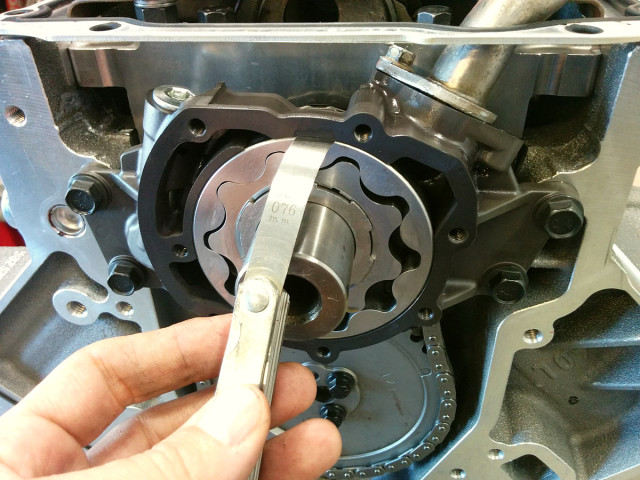

Melling says its 10295 high-pressure oil pump is calibrated to give a 10-percent increase in oil pressure. The feeler gauge was used to assure that the pump was properly centered on the crankshaft before the bolts were tightened.

Down below the stroked LS2 is oiled by a Melling 10295 high pressure oil pump drawing from a Mast Motorsports "HotRod" oil pan designed to fit the LS engine into the owner's notorious 1965 Buick Skylark. The factory GM LQ9 windage tray needed to be spaced with washers to clear the stroker crankshaft. Modifications were also performed on the tray near the front of the engine to allow it to clear the low profile oil pan. During testing the engine idled with oil pressure just above 40 psi and maintained 75 psi at higher RPM levels. Rotella 15-40 conventional oil spiked with half a bottle of Lucas Engine Break-in additive was used on the dyno.

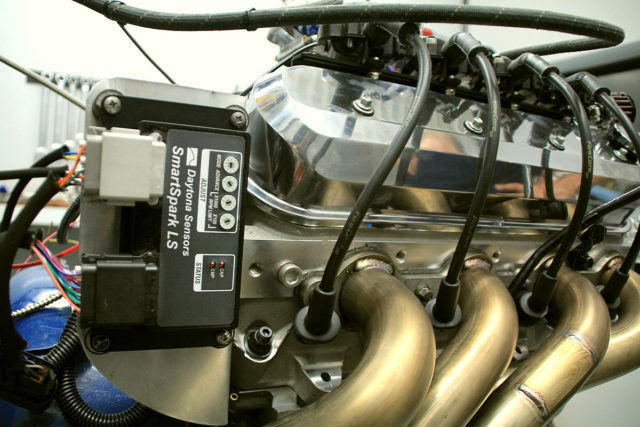

While a bit small for this application, a custom 4150 style Holley HP 835-cfm four-barrel carburetor was used for this dyno session. To light the fire, a Daytona Sensors Smart Spark LS Ignition Module controlled the factory ignition coils.

The Results

Matt and Jay Scranton have a long history in the drag racing community with multiple NMCA Super Street Championships under their belts, a stint in the NHRA Pro Stock ranks and the NHRA Sport Compact Drag Racing Series, along with the experience of working with Toyota Racing Development. Here Matt puts the engine through the paces on the dyno.

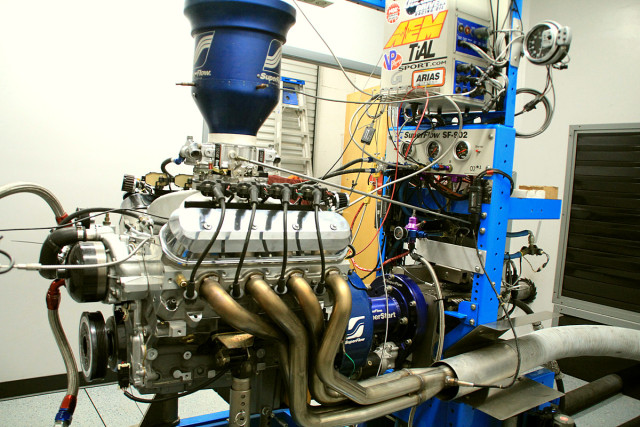

After assembly the engine was dressed out and taken to Scranton Racing Development in Land O'Lakes, Florida for dyno testing on its Superflow 902 engine dynamometer. With pre-test predictions in the 650 horsepower range, once on the dyno the engine exceeded expectations. After the engine break in procedure some initial pulls were made to ensure proper fuel curve and timing calibrations.

Joe Irwin (left) of Fast Forward Racing Engines was responsible for machining and assembling the short block, while the owner — Steven Balusik (right) — was responsible for the rest. They were both very pleased with the results.

Engine owner Steven Balusik dials in the jetting on the 835 CFM Holley carburetor. Steven says this engine would pick up at least five to 10 horsepower with a larger carburetor -- something in the 1,000 cfm range. The spark plugs were inspected after break-in for consistency and any evidence of oil. This dyno test was performed with NGK TR6 spark plugs.

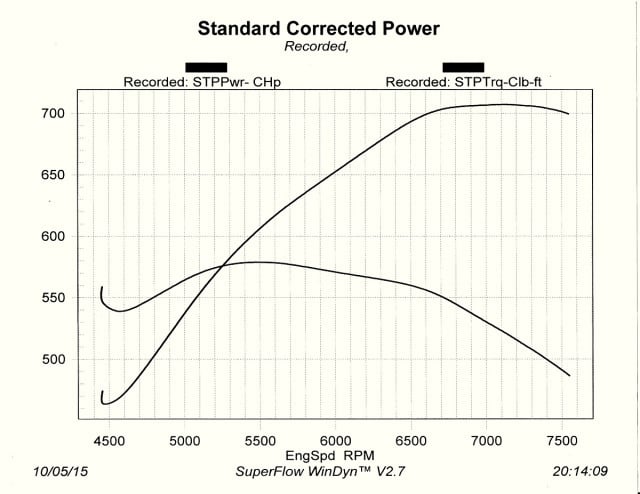

The engine impressed everyone by ripping out 707 horsepower at 7,100 rpm, and 578 lb.-ft. of torque at 5,500 rpm. This earned the 403ci LS the nickname "Little Beast." With carefully chosen parts and exceptional attention to detail, what started out as a run of the mill stroker kit upgrade escalated to an extraordinary 700 horsepower pump-gas monster.

Source: https://www.enginelabs.com/engine-tech/dyno-testing/project-escalation-a-700-horsepower-pump-gas-ls-build-with-ffre/

0 komentar:

Posting Komentar